louver pressure drop test|louver pressure drop dimensions : member club PRESSURE DROP • The sizing of a louver for a desired pres-sure drop and air flow rate is greatly simplified with the unique PRICE NOMOGRAPHS: refer to the appro-priate sheet and “How to . 3 de out. de 2023 · 31. 42. 45. 71. 80. Ganhadores. Previsão do Prêmio. R$ 700.000,00. Para o próximo sorteio do dia 04/10/2023. Distribuição de prêmios da Quina 6257. A .

{plog:ftitle_list}

Resultado da 26 de set. de 2023 · As postagens em grupos anônimos, os chamados "chans", que se notabilizam pelo ódio contra as mulheres, explodiram nos .

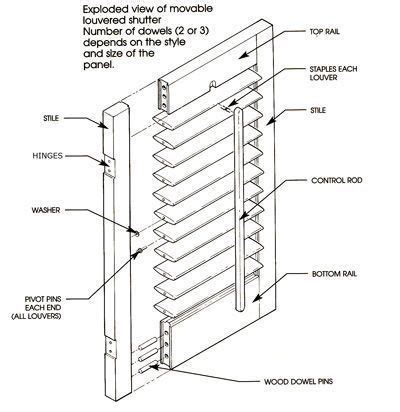

price louver parts diagram

The AMCA Standard 500-L test for pressure drop determines a louver’s resistance to airflow. Since some equipment needs air to operate effectively, airflow is an important factor.Explain louver performance terminology, including free area, pressure drop, water .(industry accepted test procedures) to ensure products meet industry standards for safety and performance in several weather situations. Basic criteria for louver performance used in .

The ANSI/AMCA Standard 500-L test for pressure drop determines a louver’s resistance to airflow. If you are considering a louver for a space containing equipment that needs air to operate effectively, the louver’s .

louvers engineering guide

louver selection procedures

PRESSURE DROP • The sizing of a louver for a desired pres-sure drop and air flow rate is greatly simplified with the unique PRICE NOMOGRAPHS: refer to the appro-priate sheet and “How to .Discover how to calculate louvre pressure drop and why it's an important factor to consider at the design or specification stage. ANSI/AMCA 550-22 – Test Method for High Velocity Wind Driven Rain Resistant Louvers deals with these conditions, establishing uniform laboratory test methods and .

This publication outlines the application of louvers, including selection for pressure drop, air leakage, water penetration, and sound reduction.

Explain louver performance terminology, including free area, pressure drop, water penetration and wind-driven rain rejection. Describe the five types of louver testing as outlined in . With louver products, the pressure drop is a measure of airflow resistance typically displayed as inches of water gauge at specific free area velocities. Free area and the . The best approach to louver selection combines the importance of understanding the value of independent third-party certified testing and the applicable test standards, with the basics of free area, pressure drop, air .

tional airflow may create more pressure drop than with standard louvers. Pub-lished Air Movement and Control Asso-ciation (AMCA)-certified pressure-drop performance does not include the effects of a bird or insect screen. This can add from 5 to 15 percent of pressure drop depending on the screen type. • Sound: Is the louver going to be sup .pressure drop to a louver. The pressure drop added by either of these screens is not enough to require a change in louver size, in most cases. However, if pressure drop is a ruling factor in louver sizing, screen choice may be important. For in-sect screens, a commonly used size is 18-16-mesh-by-0.011 in.-diameter-wire screen (roughly 65 .

bottled water ph tester

Water penetration test; Air discharge and entry loss coefficient/pressure loss. Sand trap louvres testing to EN 13181. For testing the performance of sand trap louvres used in desert-like conditions and designed for removal of sand while allowing air to flow into a building, BSRIA offers: Pre-test of sand distribution; Sand rejection effectiveness

• AMCA 550 Listed Louver. • Closely spaced vertical blades prevent the penetration of wind-driven rain, reducing damage and additional operating expenses. • Published performance ratings based on testing in accordance with AMCA Publication 511. • .2. The most common louver is 4” deep. Louvers are also made 6” deep, 2” deep and 1.5” deep. Sometimes, the 6” deep louver will have better water resistance and pressure drop properties than a 4” deep louver. Louvers with 2” or 1.5” depth are normally used when a 4” will not fit or for other aesthetic reasons. 3. Similarly, ANSI/AMCA 500-L-12 (R2015) – Laboratory Methods of Testing Louvers for Rating establishes uniform laboratory testing methods for louvers, being used to determine air leakage, pressure drop, water penetration, wind driven rain, and operational torque. However, some of the standards address louvers under specific conditions.Superseding ANSI/AMCA 500-L-2012 (Rev. 12-15), ANSI/AMCA Standard 500-L-23 establishes uniform methods of laboratory testing air leakage, air performance (pressure drop), water penetration, wind-driven-rain and wind-driven-sand resistance, and operational torque. It may be used as a basis for testing louvers with air as the test gas.

Pressure Drop @ 6,000 CFM Intake (in wg) Max Intake Volume Flow Rate (cfm) Exhaust Volume Flow Rate @ 0.15 in wg (cfm) site Submittal ft2 % PDF EDD-401 4 DD 0.081 0.081 AP, WP 8.22 51 992 0.08 8154 8312 EDD-601 6 DD 0.081 0.081 AP, WP 8.21 51 1107 0.09 9088 8399 EHM-601 6 DD 0.081 0.081 AP, WP 7.91 49 1065 0.08 8424 6577a louver’s potential air volume at a given velocity, measured in feet per minute (FPM). Example 1 Free Area Chart - in square feet Fan area does not increase proportionately with louver face area. 1. Louver #1, 24” x 24” 1.76/4 sq. ft. = 44% free area 2. Louver #2, 48” x 48” 8.32/16 sq. ft. = 52% free area 3. Louver #3, 66” x 72”

Louvers GREENHECK’S Effects of Screens on Louver Performance Application Example Let’s assume a louver has 0.10 in. wg pressure drop at a specific volume or free area velocity. If it were an intake application, the estimated overall static pressure drop including a flattened expanded aluminum birdscreen would be 0.112 in. wg (0.10 x 1.12).For example, a 1⁄2-in.-mesh-by-0.063-in.-wire screen (approximately 75-percent free area) adds roughly 5 percent to a louver’s pressure drop. Compare that to a 3⁄4-in.-by-0.051-in. expanded metal screen (approximately 70-percent free area), which will add roughly 15-percent pressure drop to a louver. The pressure drop added by either of . The three most common performance criteria in the selection of louvers are: Pressure drop. Pressure drop, also known as air performance, is the difference in pressure between two points in a flow system. . Also, it creates peer-vetted American national standards for testing louvers. The most common AMCA standard used to test and rate the .

The test measures the air pressure loss through the louver at various airflow rates and the resultant entry and discharge aerodynamic coefficient can be calculated. With these coefficient values, together with actual project louver size and airflow rate or velocity, we will be able to derive the pressure drop value for any specific project.

The air performance of a louver is described by the pressure drop across the louver for a given flow rate of air through the free area. ©2017 Slide 30 of XX. Louver Considerations. . Testing Louvers for Rating, establishes uniform test methods for determining pressure drop, water penetration, air leakage, and penetration of wind-driven rain.

The discharge loss coefficient will assign an Airflow class from 1 to 4. The higher the class, the lower the pressure drop. This is a far better method for assessing pressure drop than using the free open area as an indicator. The testing also comes with the bonus of the effectiveness classification providing an indication of water penetration.A: With respect to louver products, pressure drop is a measure of airflow resistance typically displayed as inches of water gauge at specific free area velocities. Free area and the aerodynamic properties of the louver product are among items that play a part in determining pressure drop. Lower pressure drop is generally considered more .

Ex. A sample louver's pressure drop is 0.05 in. w.g. at 1000 FPM. How does it work?: As pressure drop increases, the airflow rate will decrease. The system can overcome this by increasing the speed of its fans. .2. Explain louver performance terminology, including free area, pressure drop, water penetration and wind-driven rain rejection. 3. Describe the five types of louver testing as outlined in ANSI/AMCA Standard 500-L and how those tests are performed. 4. Explain how louvers are specified through the AMCA CRP process, andTo use this calculator, input data and select from drop-down menus. Pressure Drop, Effective Aerodynamic Area and Rain Defence Classifications will then be calculated accordingly. All Louvreclad performance louvres are tested and classified in accordance with AS/NZS 4740:2000 test standard for Natural Ventilators – Classification and Performance.Pressure Drop: Pressure drop is the difference in pressure between two points in a flow system. It is also referred to as air performance. As air is mechanicallydrawn or pushed through a louver, pressure is created due to the turbulence. The increasing pressuremeasurement of this turbulence,or “pressure drop,” at higher air velocities is an .

Pressure-drop, water-penetration, and impact testing should be verified. Impacts of Dampers and Louvers on Data-Center Design. The previous paragraphs spoke to the general application of dampers and louvers. There are, however, more complex considerations. In North America, most data centers contain generator rooms and enclosures.Our commercial louvers let architects do what they’ve always wanted to. Input the specs of your louver into the calculator to see your results. . CS can design, test and fabricate custom expansion joint cover assemblies to meet your project needs. Facade Solutions. Facade Solutions. . Pressure drop intake:---Pressure drop exhaust:---

LOUVERS 13.8 How to Size ASTL and AFSTL: Note: For optimum performance of sand trap louver with lower pressure drop and higher efficiency, we recommend a face velocity of up to 1m/s. For a known air quantity, calculate face area as follows: Face area (m2) = Air quantity (m3/sec) Face velocity (m/sec) The length (m) and width (m) ofLouver Test Sample: 48” x 48” (1.2 x 1.2), mill finish, no screen Water Application Method: wetted wall above louver and manifold above louver simulat-ing rain drops Water Flow: 4” (102) per hour rain . INTAKE PRESSURE DROP (PASCALS) MAXIMUM VOLUME MODEL .

pressure drop to a louver. The pressure drop added by either of these screens is not enough to require a change in louver size, in most cases. However, if pressure drop is a ruling factor in louver sizing, screen choice may be important. For in-sect screens, a commonly used size is 18-16-mesh-by-0.011 in.-diameter-wire screen (roughly 65 .Severe Weather Testing TAS-202: Uniform Static Air Pressure Test •Simulates a louver’s ability to resist pressure from hurricane force winds. •Testing consists of subjecting the louver to both positive and negative pressure for 60 seconds. They are tested at 75%, 100%, and 150% of the product’s design load. Passing the test is dependent .For pressure drop the new correlation reproduces 90% of the CFD data within 90% accuracy. Work is underway to physically test the small diameter tube coils with louvered fins. The heat transfer and pressure drop data obtained through this physical testing will be used to further refine the aforementioned correlations. 1. INTRODUCTION

louver pressure drop dimensions

WEB17 de fev. de 2024 · Yasmin Brunet, Mel Maia e Duda Rubert viveram romance com MC Daniel — Foto: Matias Ternes/reprodução. Não é novidade que MC Daniel tem sido um dos funkeiros de mais destaque da cena nos .

louver pressure drop test|louver pressure drop dimensions